(Click on the image for a larger view) |

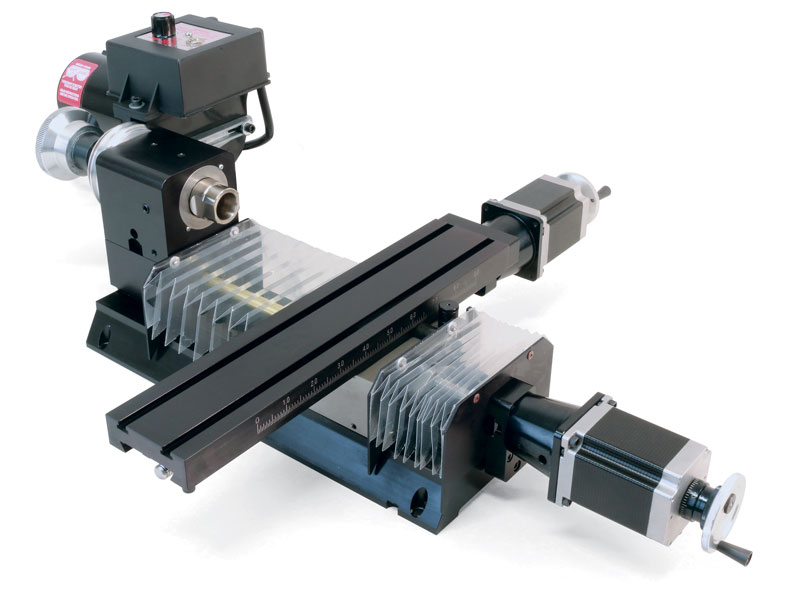

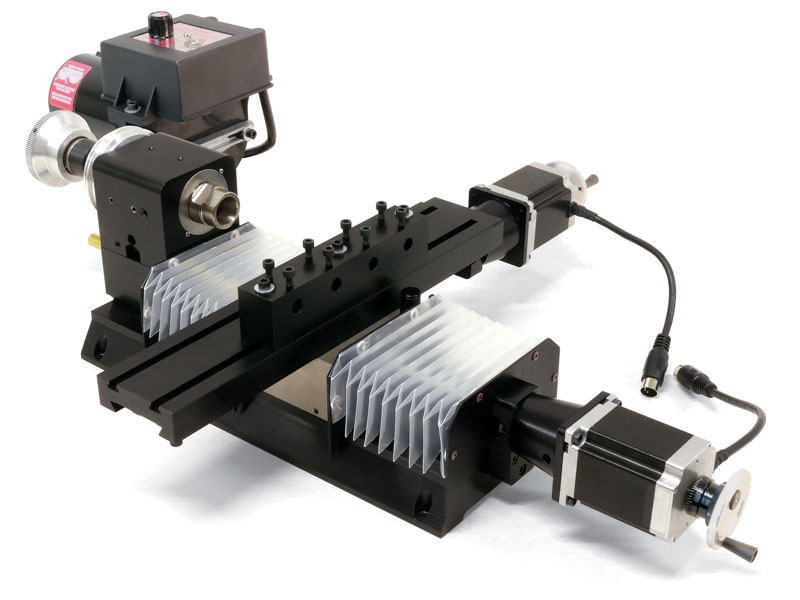

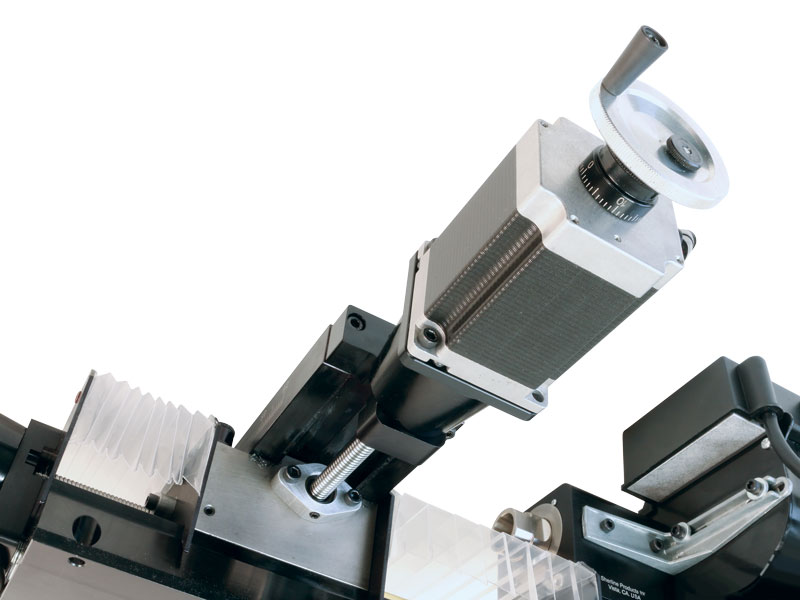

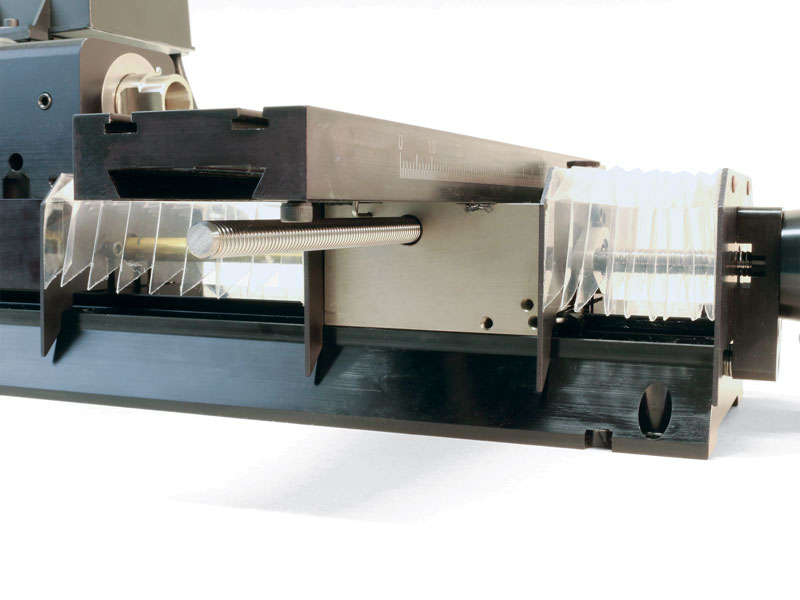

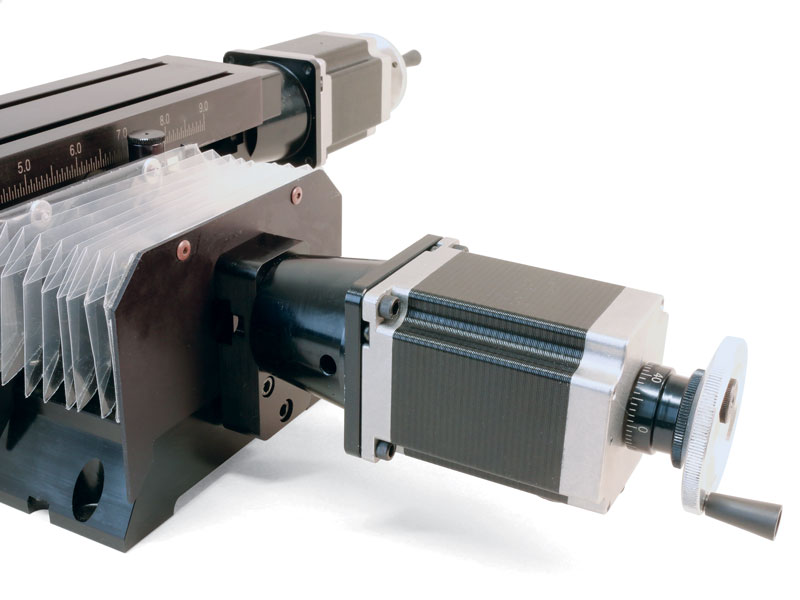

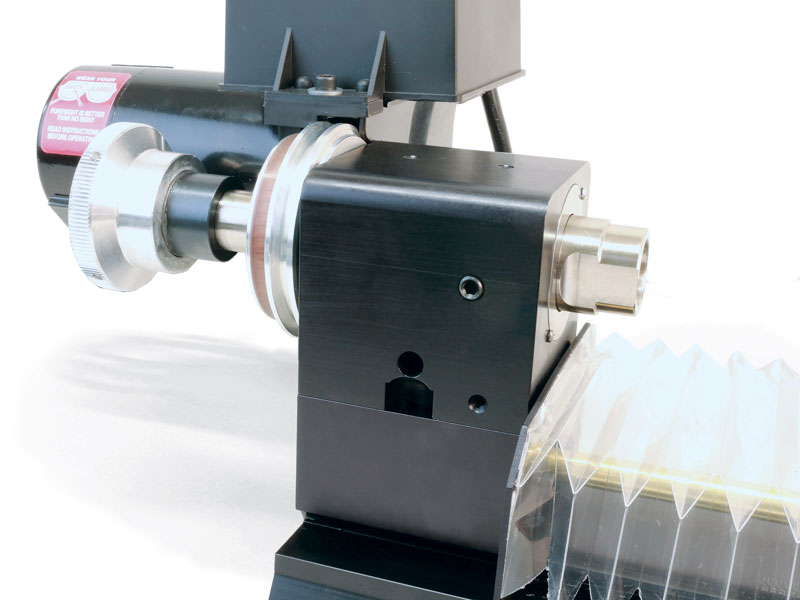

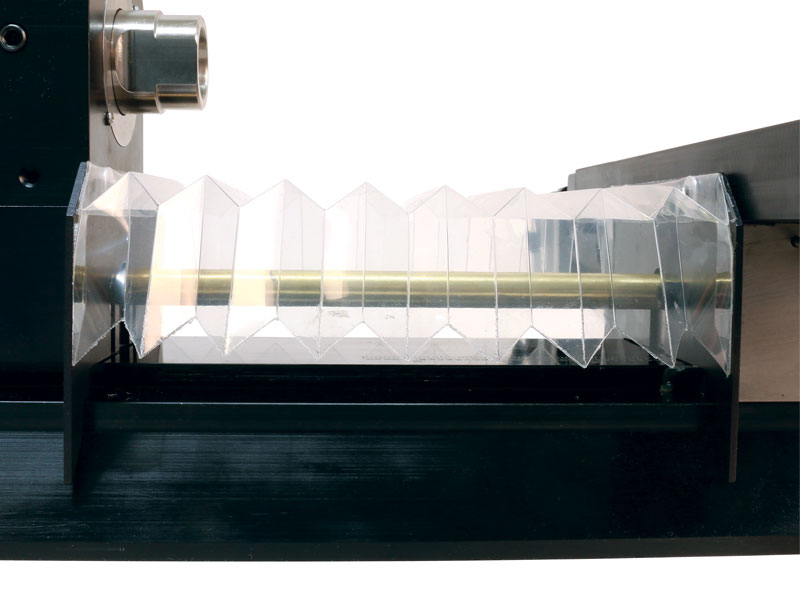

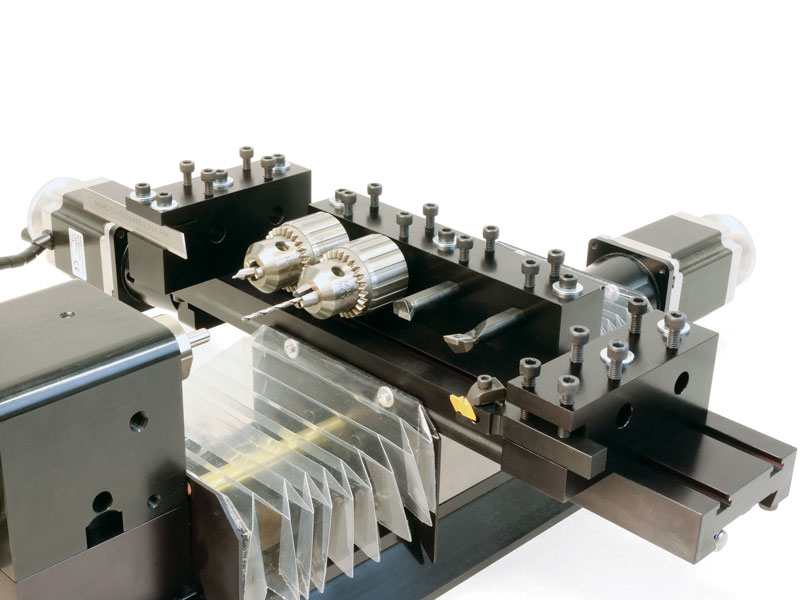

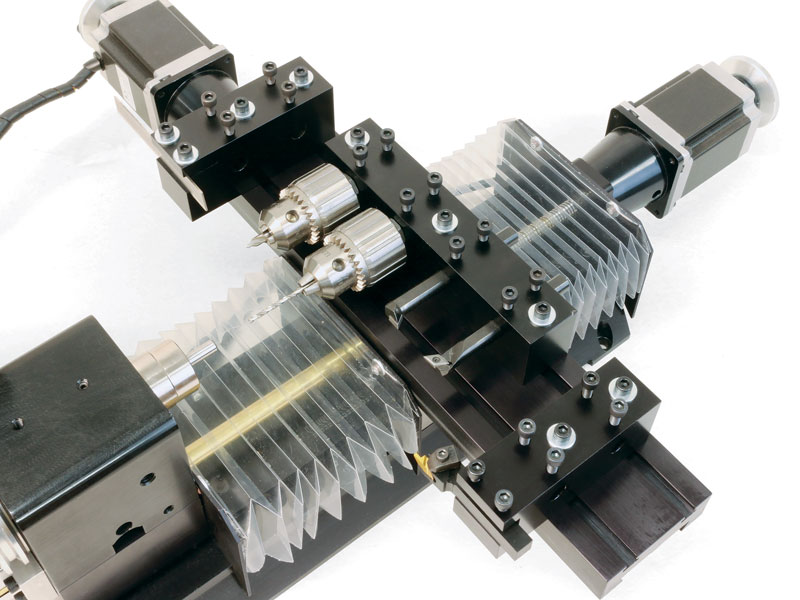

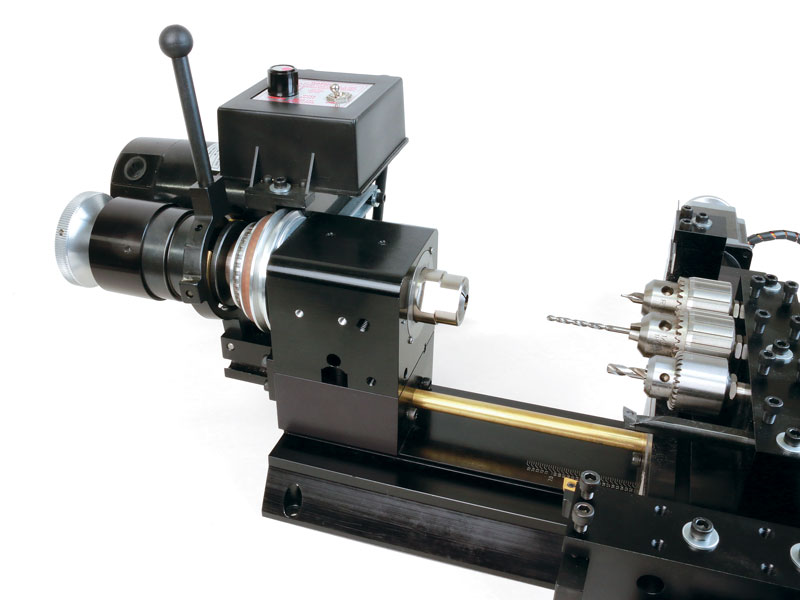

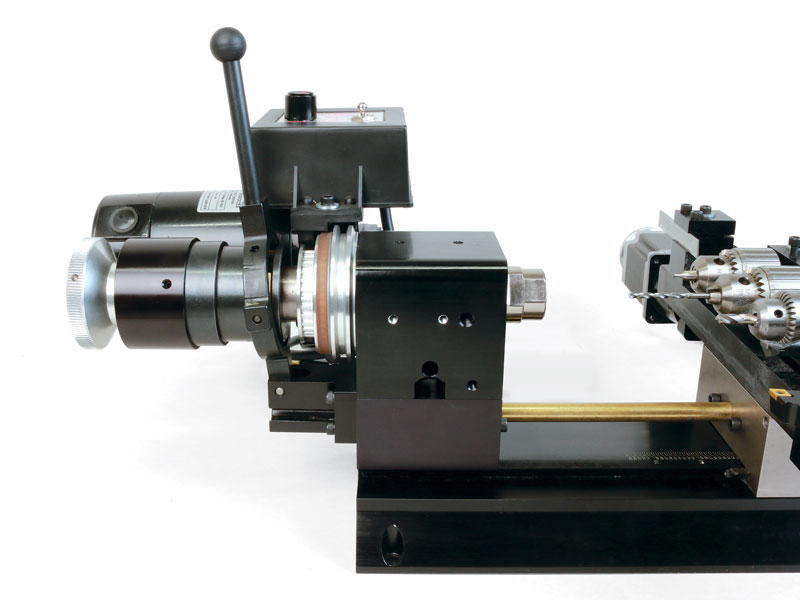

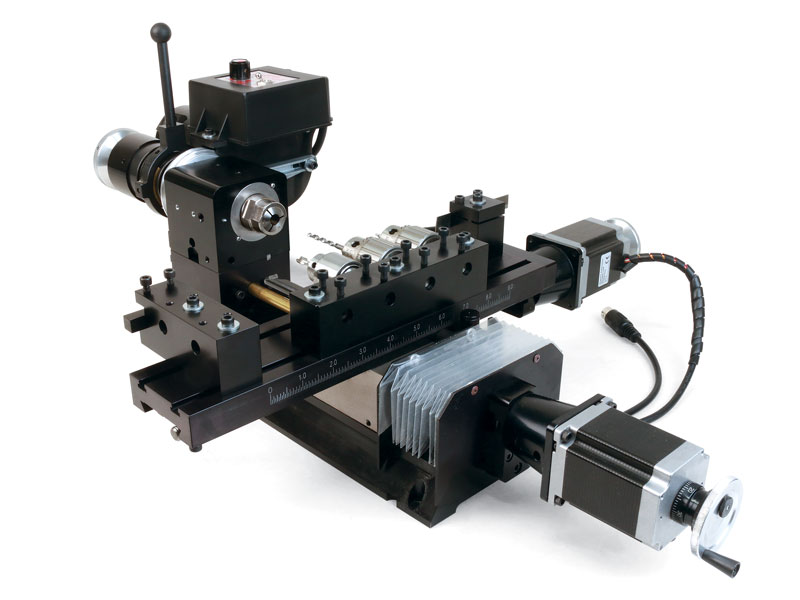

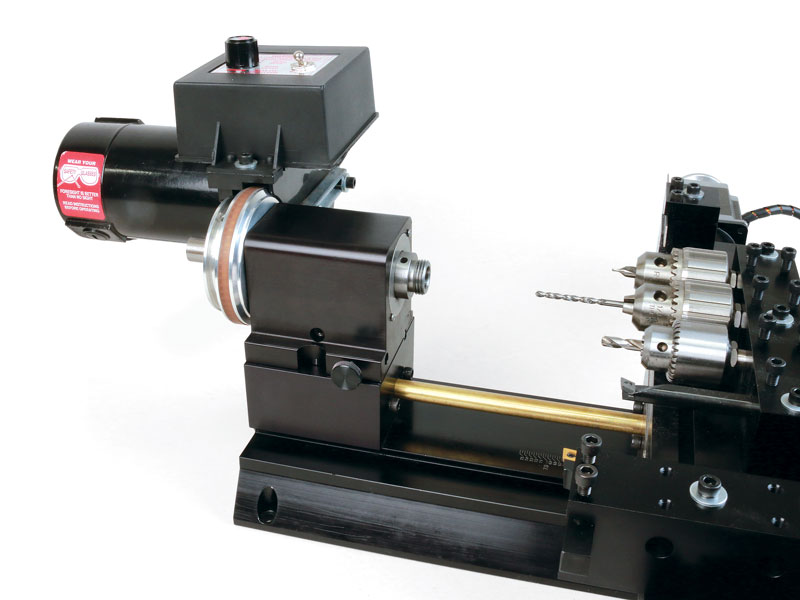

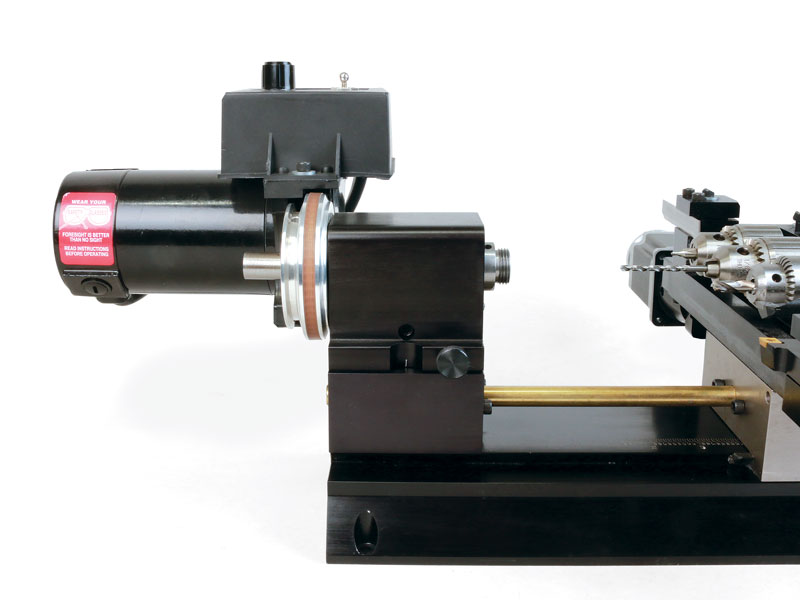

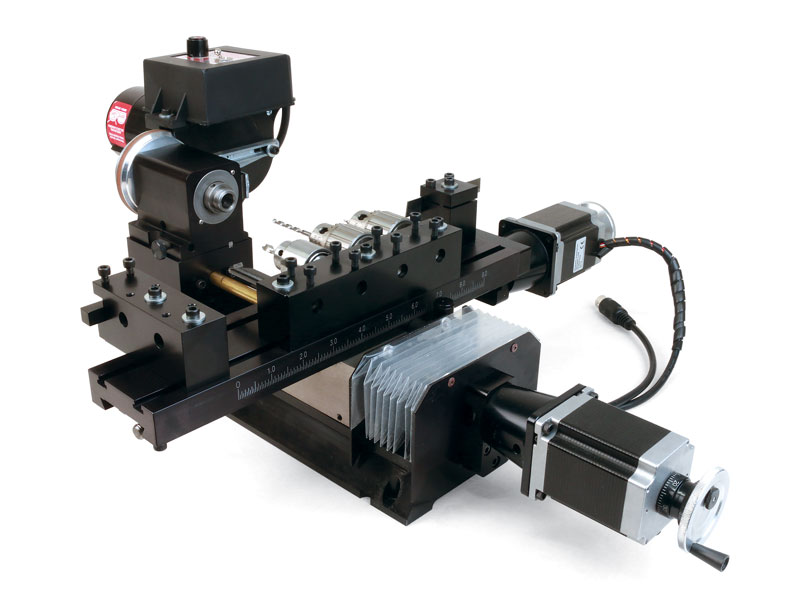

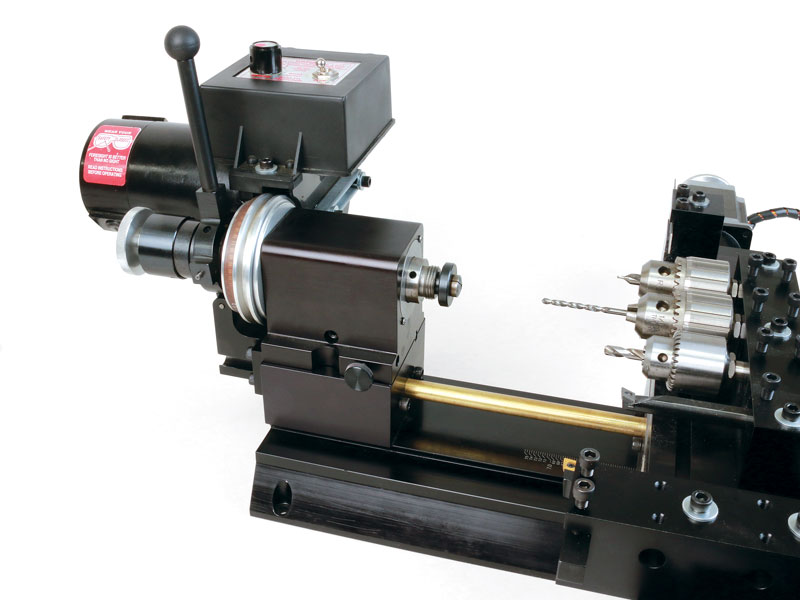

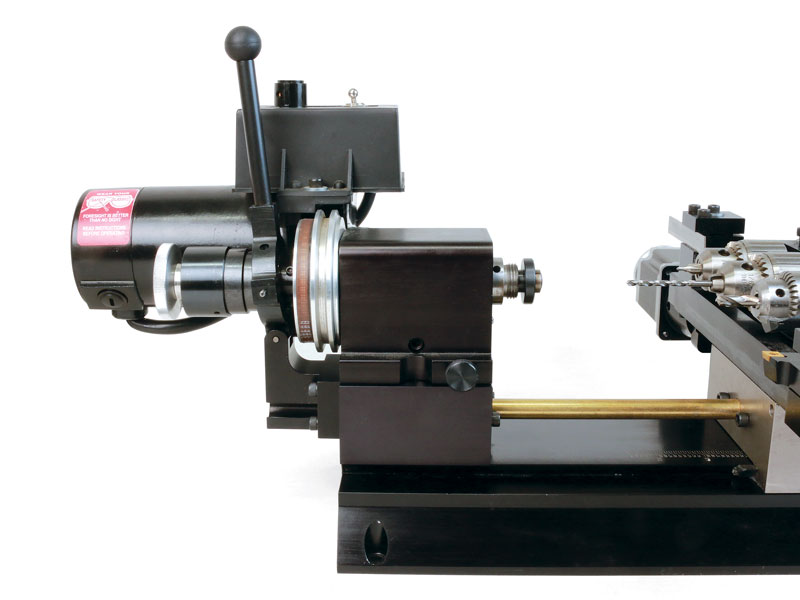

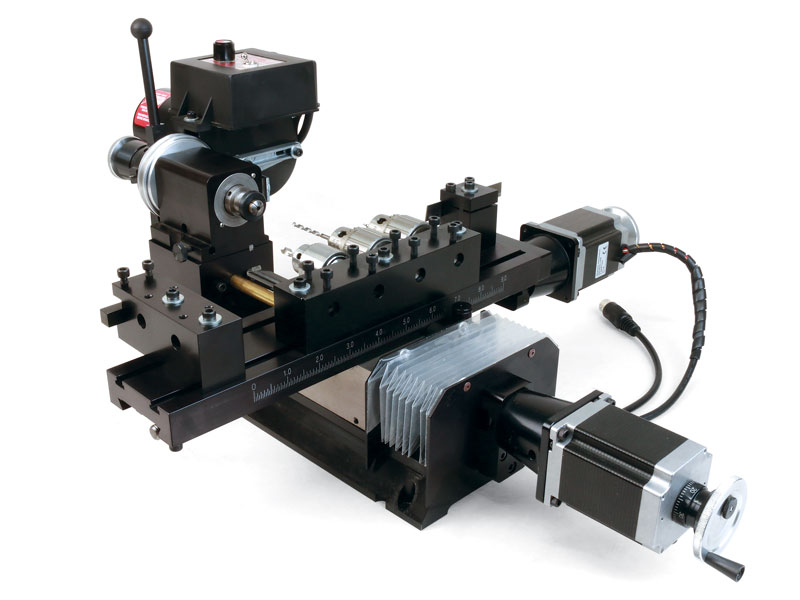

CNC Chucker Lathe

*Click on the CONFIGURE NOW button to select the upgrade options at the Chucker product page. Back to top |

Standard Features Include:

|

Optional Accessories for the Chucker Lathe18" Extended Table 18" Extended Base |

Below are all of the configuration options for our Chucker Lathe. Click the More Info links on any of the products for more detailed descriptions and specifications.

Headstock Options: |

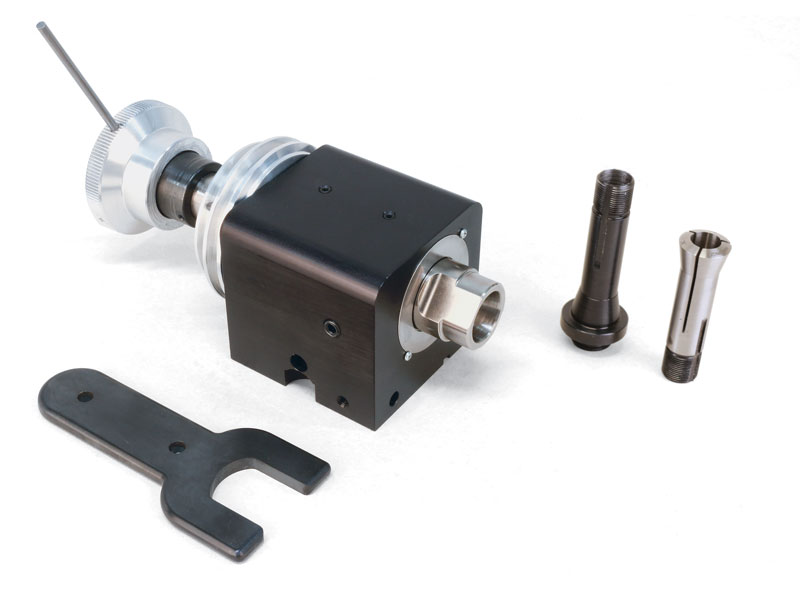

3C Collet Headstock. |

|||

Table Options: |

13" Table Travel: 9.25" (234.95 mm) | 18" Table Travel: 12.8" (325.12 mm) | ||

Base Options: |

14" Base Travel: 7" (177.8 mm) | 18" Base Travel: 11" (279.4 mm) | ||

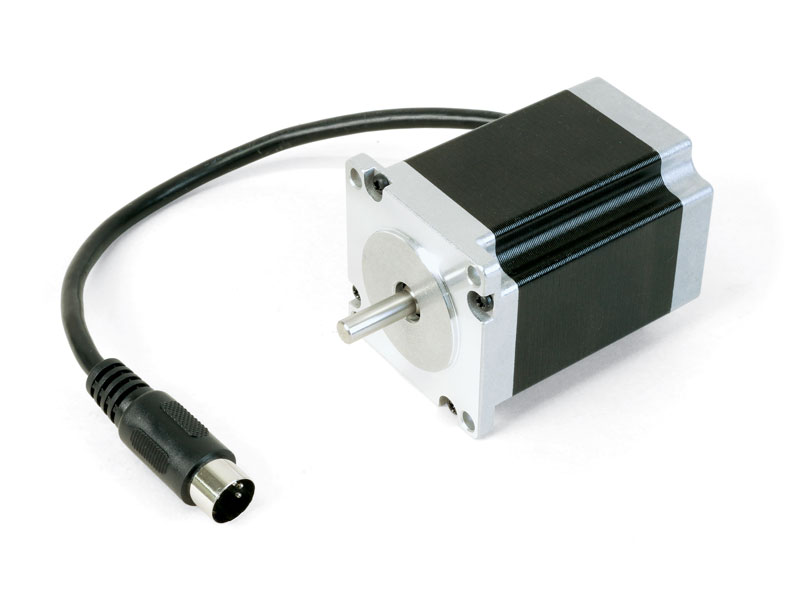

Stepper Motor Options: |

High-Torque Stepper Motors More Info... |

|||

Driver Box Options: |

Standard 4-Axis Linux Driver Box. More info.... |

LinuxCNC Computer System with Driver Box More Info... |

MASSO Controller with Driver Box |

|

|

Always wear safety glasses when operating machine tools. |

|

Download PDF Sherline/MASSO Chucker Lathe Tool Calibration Instructions |

Ball Screw Machine Specifications:

|

Ball Leadscrew Specifications:

Stepper Motor Specifications:

|

Chucker Lathe Photo Gallery

Search Our Site