|

The photo above shows a typical powered slide. They are available in several lengths, in 1-axis, 2-axis or multi-axis form and with several different configurations of base and movement. All are now available with either inch (20 TPI) or metric (1mm pitch) leadscrews and a controller programmed for the appropriate pitch. These slides are driven by a NEMA 23 stepper motor controlled by input at the stand-alone keypad. Programming is simple and controls speed, direction, and distance. (Click on image for a larger view) |

NEW! Ball Screws Now AvailableOur CNC Programmable industrial slides are now available with ball screws. Low friction in ball screws yields high mechanical efficiency compared to other leadscrew alternatives, and efficiencies can range from 70% to 95%. See below for details and call for a quote. FeaturesSherline offers single-axis controllers to drive the stepper motor on any individual axis of the lathe or mill. No separate computer or drivers are needed. The keypad/control unit has its own computer chip built in. It is all ready for you to use the keypad to drive the stepper motor directly or to enter simple program commands to do sequenced operations. Parameters that can be entered are direction, distance to travel, feed rate and whether or not the program pauses to wait for another command or proceeds to the next step. Up to 40 programmed steps of four parameters each can be entered into either of two separate user-settable programs. Controllers can be interconnected with a cable to signal each other to act in sequence. They can also be connected to other CNC system controllers to communicate with "sense" and "acknowledge" signals so that they perform their preprogrammed functions at the proper time during a CNC program sequence. The stepper motor mounts feature dual ball bearings with a preload nut to eliminate endplay. A dampened coupling connects the 1/4" diameter shaft of the stepper motor to the leadscrew. Use of a dual-shaft stepper motor allows manual cranking by means of the supplied handwheel as an alternative to computer-controlled movement. The controller uses micro-stepping to provide accurate, smooth travel. All of these slides are also available with manual handwheels instead of stepper motor mounts. See our page on Manual slides. Weight Capacity and Duty CycleThe weight capacity of our slides is about 10 lbs. depending on where the weight is located and how long the table is. On an 18" table you should not go more than 10 lbs. of weight at the end of the table (there is a leverage factor). If the weight is going to be more centrally located (closer to the base), then you can exceed the 10 lbs. limit. Duty Cycle: Our tables are black anodized and the base is hard black anodized. We use our slides in our shop to manufacture our own parts. They run (8) hours a day, (5) days a week. Under this heavy constant use the dovetail area of the slide will start to show some wear on the anodize after one year (2080 hours). They are still fully functional at this point, but the anodize is beginning to wear thin. If you keep the dovetail and the screw lubricated with light oil, they will last longer. NOTE: Do not use WD40 as a lubricant on these slides. WD40 will remove the anodized coating from these parts! The leadscrews have a rolled thread which is hardened a bit by the rolling process. The backlash nuts are brass. The nut is the softer material and therefore it is the part that wears out. The backlash nut is adjustable so it can compensate for the wear until the threads are gone. You should get the same (2080 hour) duty cycle from the backlash nut before it will need to be adjusted or replaced. 3D DrawingsSherline now offers 3D CAD files for many of our most popular slides and spindles in .IGS format for designers who need to spec our parts into their machine designs. For those who need a free .IGS file viewer, see http://igsviewer.com/. (Make sure to click on the correct download link. The page promotes a number of other downloads and can be confusing.) |

Single-axis CNC Machine Slide with Controller w/8" table

(Click on image for a larger view) |

Back to top |

Single-axis CNC Machine Slide with Controller w/13" table

(Click on image for a larger view) |

Back to top |

Single-axis CNC Machine Slide with Controller w/18" table

(Click on image for a larger view) |

Back to top |

CNC Accessories

CNC 4" Rotary Table with Stepper Motor

(Click on image for a larger view) Also available with motor-mount only and without stepper motor as P/N 3700-CNC |

See Accessories page for 3701 right angel attachment or 3702 right angle adjustable tailstock for vertical mounting. Back to top |

CNC 4" Rotary Indexer with Programmable Motion Controller

(Click on image for a larger view) |

See Accessories page for 3701 right-angel attachment or 3702 right-angle adjustable tailstock for vertical mounting. Back to top |

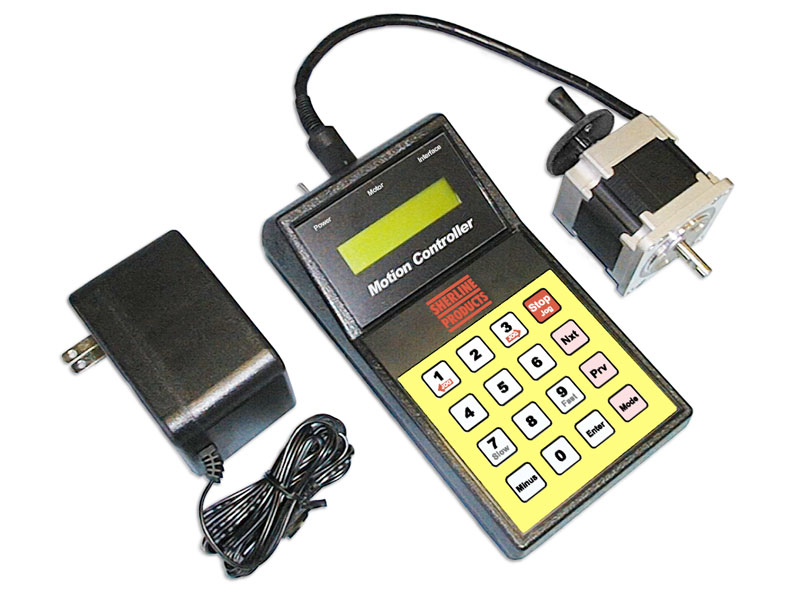

CNC Linear Motion Controller with Stepper Motor

(Click on image for a larger view) |

Back to top |

4-axis CNC Driver Box

(Click on image for a larger view) |

*Computer requires 25-pin parallel port for connection. Does not work with USB. Back to top |

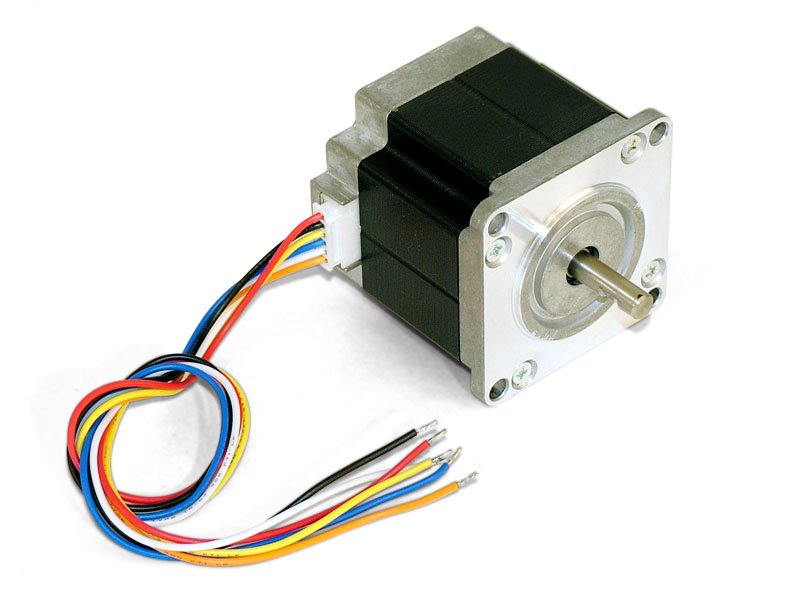

High-Torque Stepper Motor*

(Click on image for a larger view) |

*ATTENTION: This new high-torque stepper motor requires a special CNC coupling (P/N 671052, sold separately). Click on P/N link for details. Back to top |

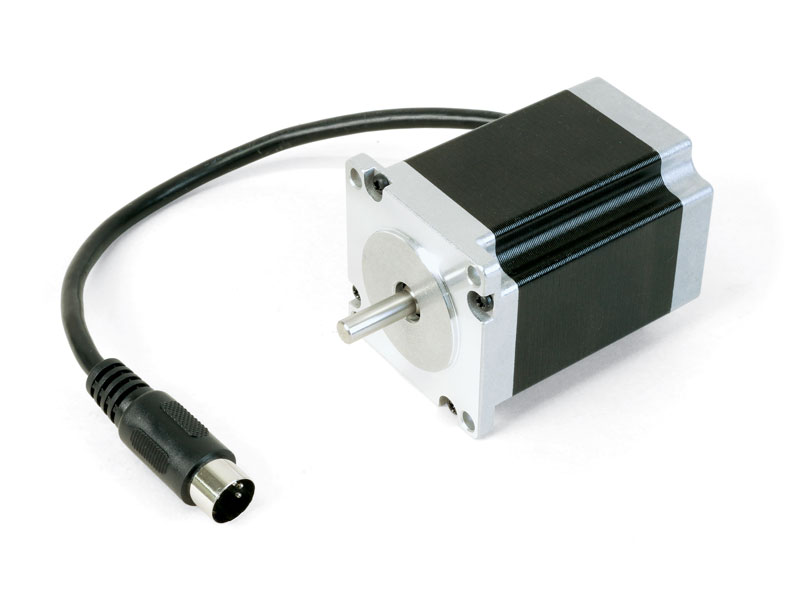

Stepper Motor with plug

(Click on image for a larger view) |

Back to top |

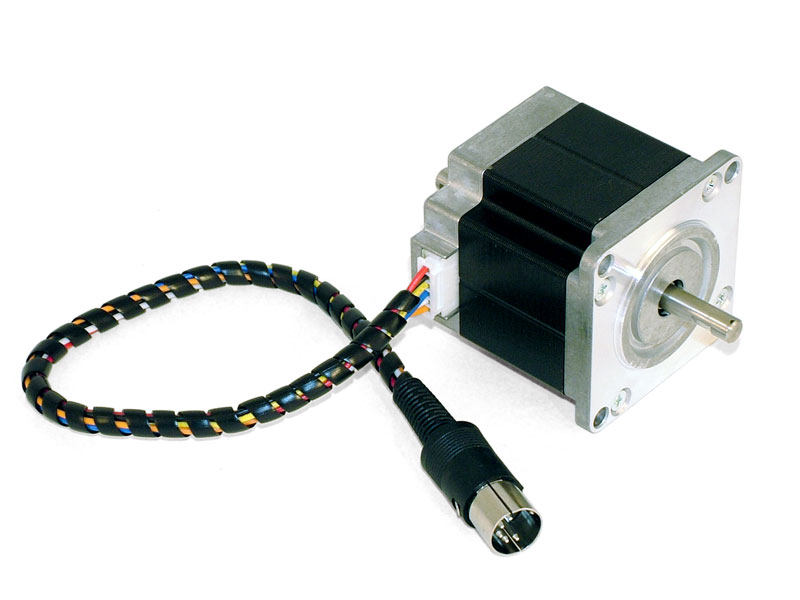

Stepper Motor without plug

(Click on image for a larger view) |

Back to top |

Search Our Site