The photo above shows a typical CNC-ready machine slide. They are available in several lengths up to 18" long, in 1-axis, 2-axis or multi-axis form and with several different configurations of base and movement. The units are priced without stepper motors so that you have the choice of either supplying your own or purchasing stepper motors as an option. They can be controlled by Sherline's single axis programmable controllers, Sherline's full 4-axis CNC system, or by your own CNC drivers. (Click on image for a larger view)

3D DrawingsSherline now offers 3D CAD files for many of our most popular slides and spindles in .IGS format for designers who need to spec our parts into their machine designs. For those who need a free .IGS file viewer, see http://igsviewer.com/. (Make sure to click on the correct download link. The page promotes a number of other downloads and can be confusing.) |

NEW! Ball Screws Now AvailableSelect CNC-Ready* industrial slides are now available with ball screws. Low friction in ball screws yields high mechanical efficiency compared to other leadscrew alternatives, and efficiencies can range from 70% to 95%. See below for details and contact us for a quote. *NOTE: Ball screws are NOT available on manual or CNC programmable controller configurations at this time. FeaturesDovetailed tables and saddles have adjustable gibs to eliminate play. The slides are manufactured primarily from 6061-T6 aluminum and finished with a black anodizing. Some slides have ground steel beds. Handwheels have a red anodized finish and the markings are laser engraved through the black finish into the white aluminum for high visibility. Handwheels are graduated in .001" increments on inch slides and in .01mm increments on metric slides. Leadscrews are precision rolled from steel, and are located under the table, out of the way of chips and coolant. Backlash is adjustable. These slides come with a stepper motor mount to which you apply your own stepper motor and controls. The stepper motor mounts feature dual ball bearings with a preload nut to eliminate endplay. A dampened coupling connects the 1/4" diameter shaft of the stepper motor to the leadscrew. The mounts are designed to accept a 23 frame size stepper motor. With the exception of the rotary motion controller, the slides are CNC-ready, which means in addition to a stepper motor you must also supply the computer, driver and software to control them. Individual-axis linear controllers are available from SherlineIPD, or the slides may be used in conjunction with your own existing CNC system. Use of a dual-shaft stepper motor allows manual cranking by means of the supplied handwheel as an alternative to computer-controlled movement. Sherline Industrial Products Division offers optional high quality, properly sized stepper motors. They are 2 amp, 136 oz/in motors with 400 step/rev resolution. They have a 1/4" shaft at both ends, so they can be driven either by computer control or manually with a handwheel. Manual handwheel slides and linear controlled slides are available with standard leadscrews only at this time. See our page on Manual slides. If you want fully programmable control over each axis from it's own individual controller, see our CNC Slides Page. Weight Capacity and Duty CycleThe weight capacity of our slides is about 10 lbs. depending on where the weight is located and how long the table is. On an 18" table you should not go more than 10 lbs. of weight at the end of the table (there is a leverage factor). If the weight is going to be more centrally located (closer to the base), then you can exceed the 10 lbs. limit. Duty Cycle: Our tables are black anodized and the base is hard black anodized. We use our slides in our shop to manufacture our own parts. They run (8) hours a day, (5) days a week. Under this heavy constant use the dovetail area of the slide will start to show some wear on the anodize after one year (2080 hours). They are still fully functional at this point, but the anodize is beginning to wear thin. If you keep the dovetail and the screw lubricated with light oil, they will last longer. NOTE: Do not use WD40 as a lubricant on these slides. WD40 will remove the anodized coating from these parts! The leadscrews have a rolled thread which is hardened a bit by the rolling process. The backlash nuts are brass. The nut is the softer material and therefore it is the part that wears out. The backlash nut is adjustable so it can compensate for the wear until the threads are gone. You should get the same (2080 hour) duty cycle from the backlash nut before it will need to be adjusted or replaced. |

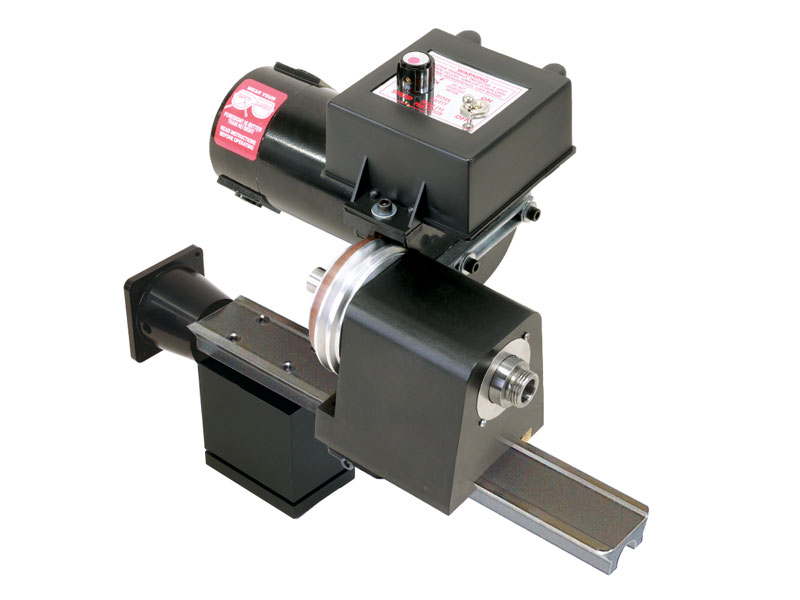

Single-Axis CNC-Ready Machine Slide with Dovetailed Headstock, DC Motor and Speed Control

(Click on image for a larger view) NOTE: We do not sell the collets used with the ER-16 spindle. Those are available through MSC Industrial Supply Co. or other tool supply sources. |

ER-16 Spindle

Back to top |

Single-Axis CNC-Ready Slide w/8" Table

(Click on image for a larger view) Ball screw option includes an electroless nickel/Teflon plated base. Contact us for a quote. |

Back to top |

Single-Axis CNC-Ready Slide w/13" Table

(Click on image for a larger view) Ball screw option includes an electroless nickel/Teflon plated base. Contact us for a quote. |

Back to top |

Single-Axis CNC-Ready Slide w/18" Table

(Click on image for a larger view) Ball screw option includes an electroless nickel/Teflon plated base. Contact us for a quote. |

Back to top |

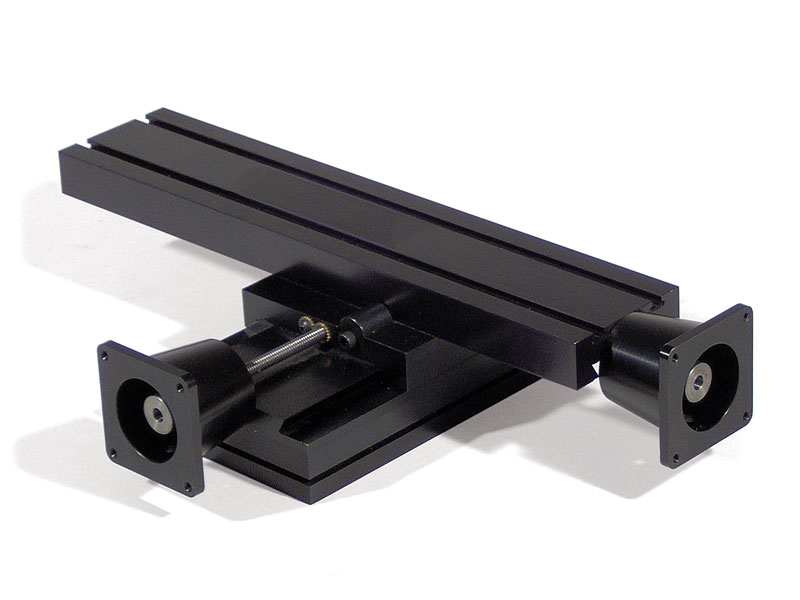

2-Axis CNC-Ready Machine Slide (on 8" XY Base) w/13" Table

(Click on image for a larger view) Ball screw option includes an electroless nickel/Teflon plated saddle. Contact us for a quote. |

Back to top |

2-Axis CNC-Ready Machine Slide (on 8" XY Base) w/18" Table

(Click on image for a larger view) Ball screw option includes an electroless nickel/Teflon plated saddle. Contact us for a quote. |

Back to top |

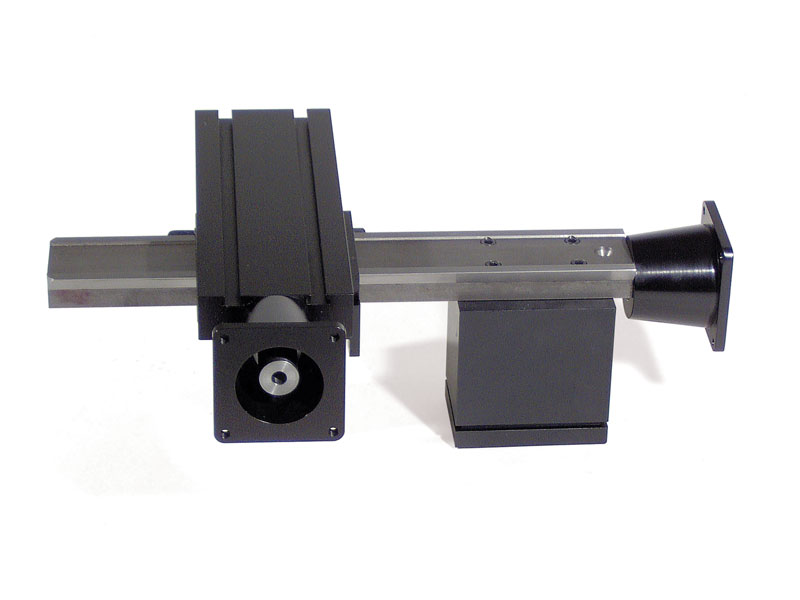

2-Axis CNC-Ready Machine Slide (w/Steel Bed on Raised Base)

(Click on image for a larger view) Ball screws are NOT available with this configuration |

Back to top |

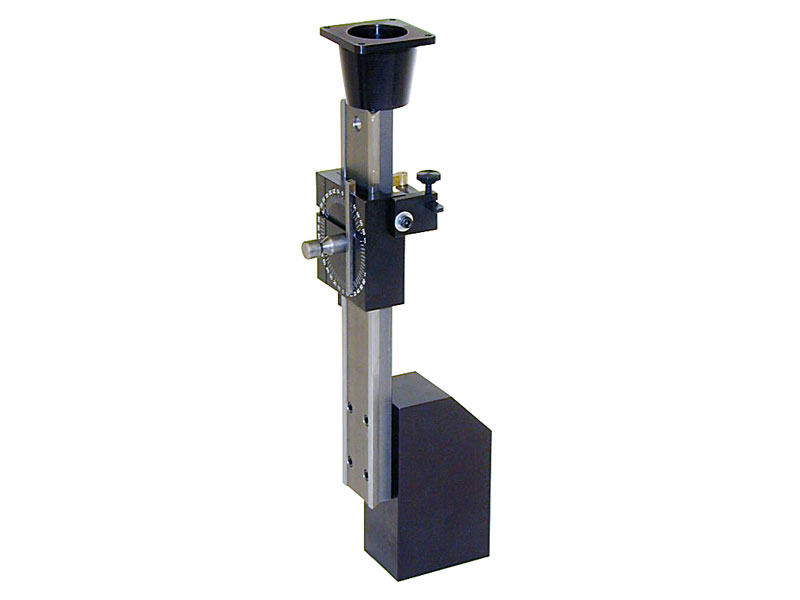

Vertical CNC-ready machine slide (with headstock saddle)

(Click on image for a larger view) Accepts P/N 8800 programmable single axis control (See below) Ball screw option: Upgrade to a 15" mill column bed with nickel coating is available. Contact us for a quote. |

Back to top |

6-Direction, 2-Axis CNC-Ready Machine Slide

(Click on image for a larger view) Ball screw option: Upgrade to a 15" mill column bed with nickel coating is available. Contact us for a quote. |

Back to top |

CNC Accessories

CNC-Ready 4" Rotary Table

(Click on image for a larger view) Also available as full CNC with stepper motor as P/N 8730 |

See Accessories page for 3701 right angel attachment or 3702 right angle adjustable tailstock for vertical mounting. Back to top |

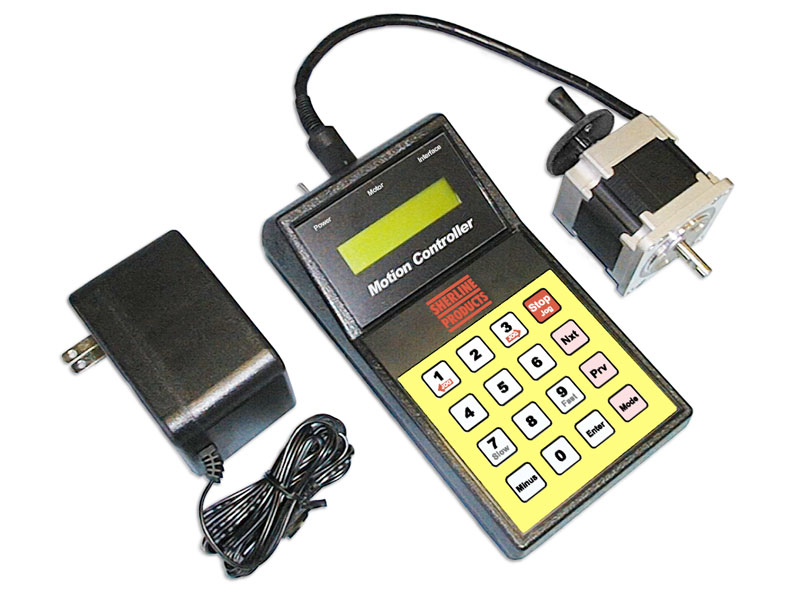

CNC Linear Motion Controller with Stepper Motor

(Click on image for a larger view) |

Back to top |

4-axis CNC Driver Box

(Click on image for a larger view) |

*Computer requires 25-pin parallel port for connection. Does not work with USB. Back to top |

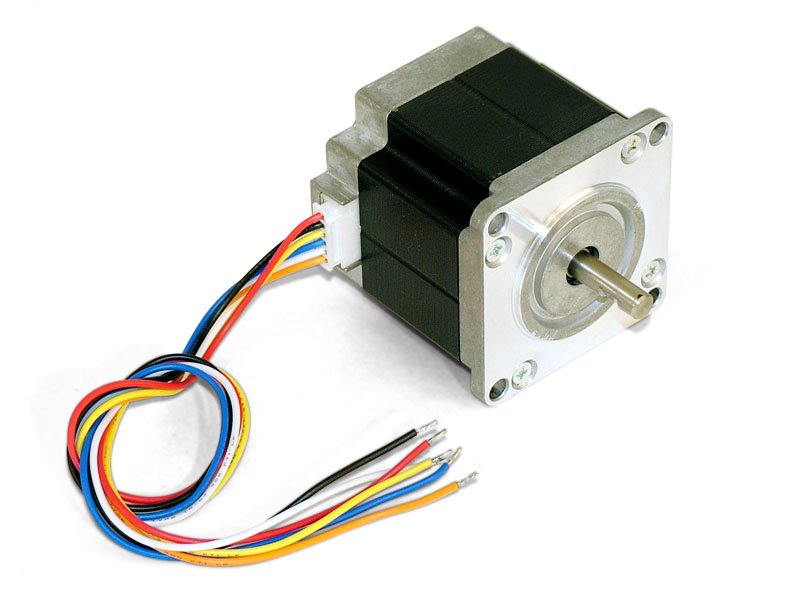

High-Torque Stepper Motor*

(Click on image for a larger view) |

191.17 oz/in (ounce inch) 11.948 in/lb (inch pound) *ATTENTION: This new high-torque stepper motor requires a special CNC coupling (P/N 671052, sold separately). Click on P/N link for details. Back to top |

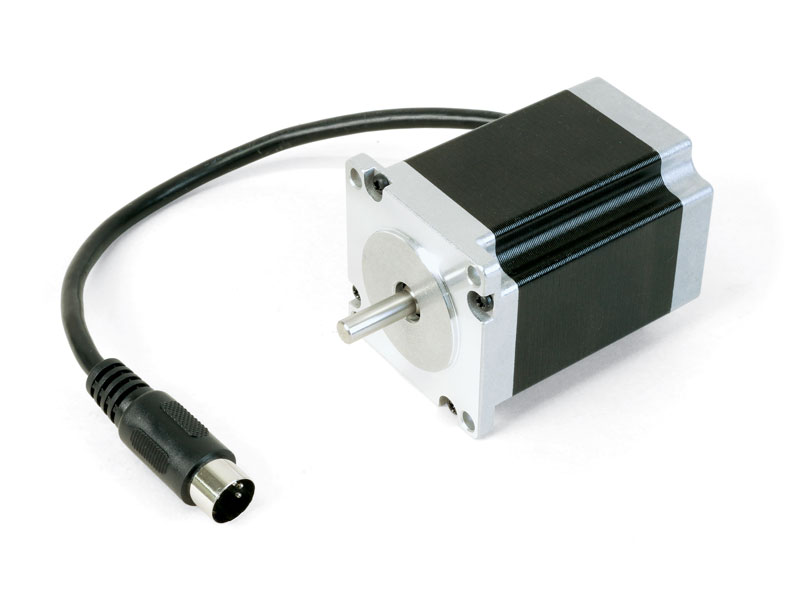

Stepper Motor with plug

(Click on image for a larger view) |

Back to top |

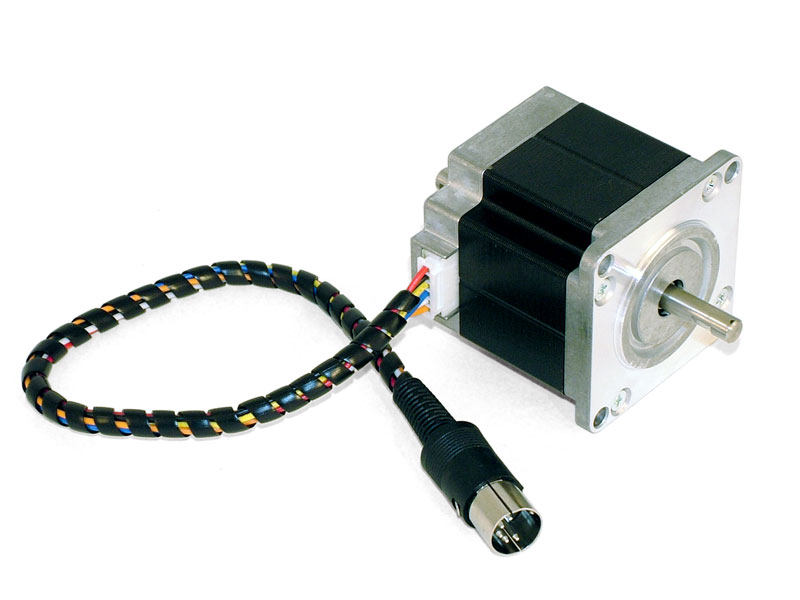

Stepper Motor without plug

(Click on image for a larger view) |

Back to top |

Search Our Site