A rotary table used in conjunction with a mill allows a machinist to produce virtually any part they can design. Sherline’s rotary table is a precision piece of equipment that has been designed to work with their vertical milling machines, however, it can be used on any mill whenever the small 4-inch size would be an advantage. The only limits are size, not complexity. |

FeaturesSherline offers one of the finest small rotary tables on the market. It is available in manual or stepper motor drive modes. It can even be purchased with its one controller to be used as a programmable indexer. It's popular among industrial shops due to its compact size, solid construction, and long-lasting accuracy. The rotary table also is available with larger, 15/32" through hole to which you can mount our chucks. This modification came about after requests from our laser engraving customers. The larger through hole allows for larger stock to be held. It also has a Nickel-Teflon plating on it because it was designed to be used in an every-day production environment. This gives the table a rust resistant surface that is hard and has added lubrication qualities. Specifications

Weight CapacityWe are stating the following weight limits for our rotary tables for continual use.

The rotary tables can hold more weight when they are not under a continual load. Use in Laser Marking SystemsSherline’s rotary table offers an accurate, stable platform for rotary laser marking applications. Its compact size makes it a good fit in small enclosures. Visit our Video page to watch a Sherline CNC-ready rotary table in use in a laser marking application on round parts, illustrating the difference between trying to mark on a round part without rotating it vs. rotating it. Some of the videos are from Jimani Inc. Laser Marking Systems who use a high-speed motor to drive the table. |

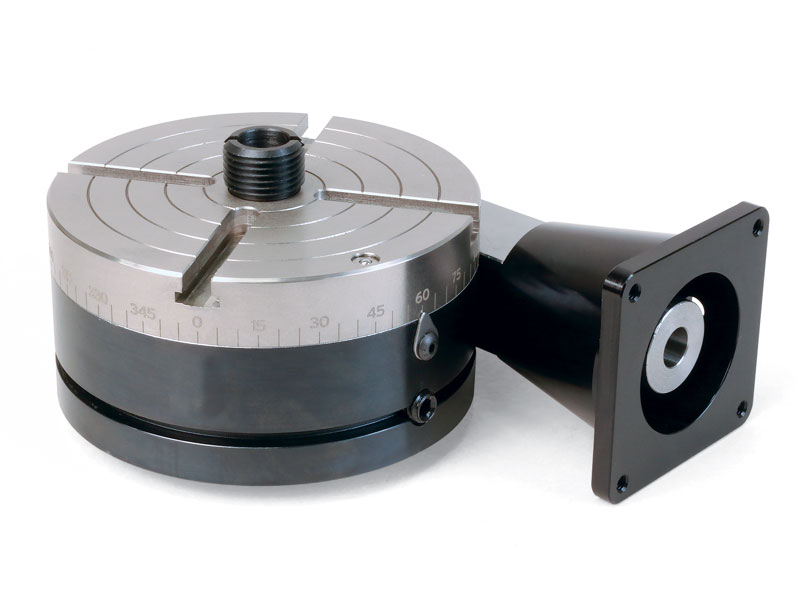

4" Manual Rotary Tables

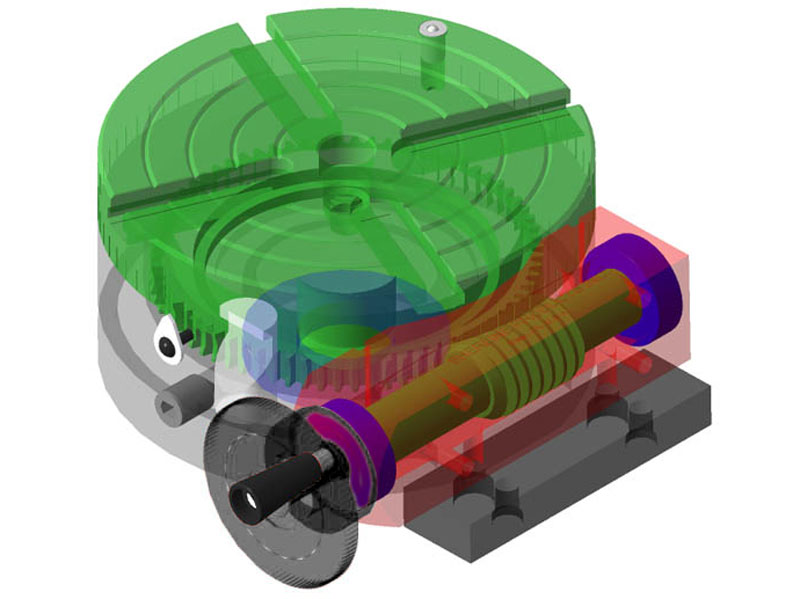

The 3D rendering on the right is a ghost view of the rotary table, drawn in SolidEdge® by John Costello, shows the internal mechanism so you can see how the worm gear drives the table. Ball bearings are shown in dark blue (Click on images for a larger view). |

Standard 4" Rotary TableThe table T-slots are identical to those used on the Sherline mill and lathe, making the vast line of Sherline tooling available for use with this product. Also included is an adapter that allows Sherline’s 3- and 4-jaw chucks to be screwed directly to the rotary table.

NOTE: Because components of the table are ground as a set during production, the P/N 3700 rotary table cannot be upgraded to the P/N 3700-CNC version later on. A new rotary table with stepper motor worm housing must be purchased. Back to top |

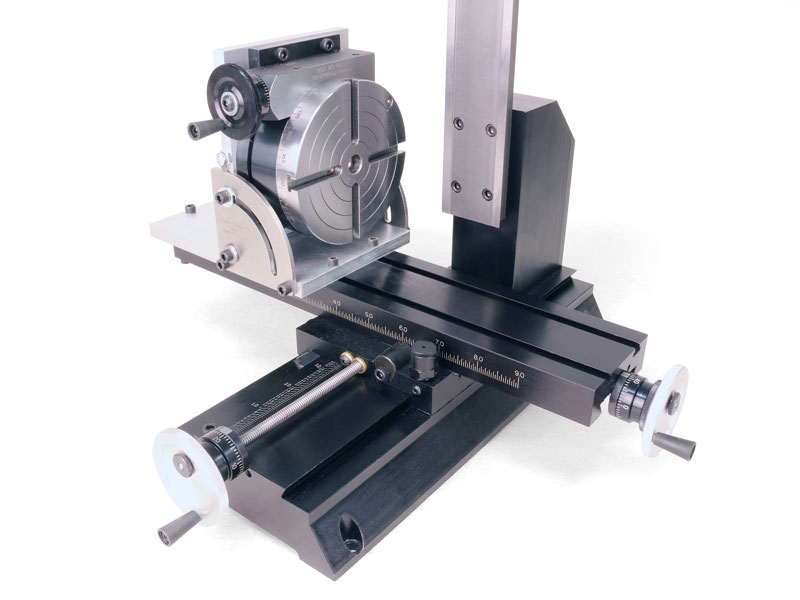

The photo on the right shows the P/N 3700-OP mounted to an optional P/N 3750 Tilting Angle Table (Click on images for a larger view). |

4" Reverse Rotary TableThe reverse rotary table is perfect for using on the tilting angle table (P/N 3750). The reverse mount allows access to the handwheel from the front of the machine (see 3700-OP Set photo up). If you used a standard rotary table in the previously described set-up the handwheel would be mounted facing the backside of the X-axis.

COMING SOON: .IGS 3D CAD file NOTE: When the worm housing is reversed to the opposite side, a clockwise rotation of the handwheel or stepper motor will result in a counter-clockwise rotation of the rotary table. Back to top |

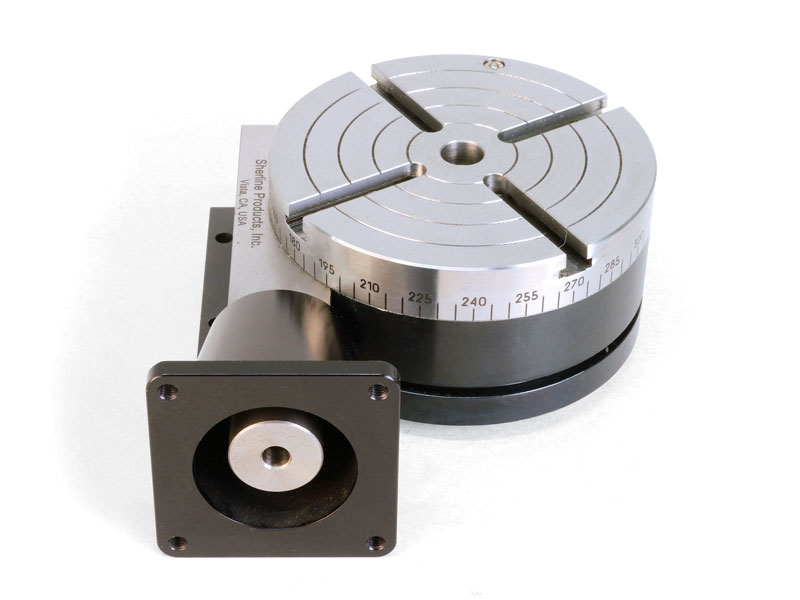

The photo on the right is the P/N 3710-CNC Rotary Table with a chuck in place to show the through hole. The CNC-ready version and chuck are shown for reference only; the chuck is not included. (Click on images for a larger view).

|

4" Nickel-Teflon Coated Manual Rotary Table w/ 15/32" Through HoleThis is a modification of our P/N 3700 4" Manual Rotary Table. This modification came about after requests from our laser engraving customers. They wanted a rotary table that had a larger through hole to which you could mount our chucks.

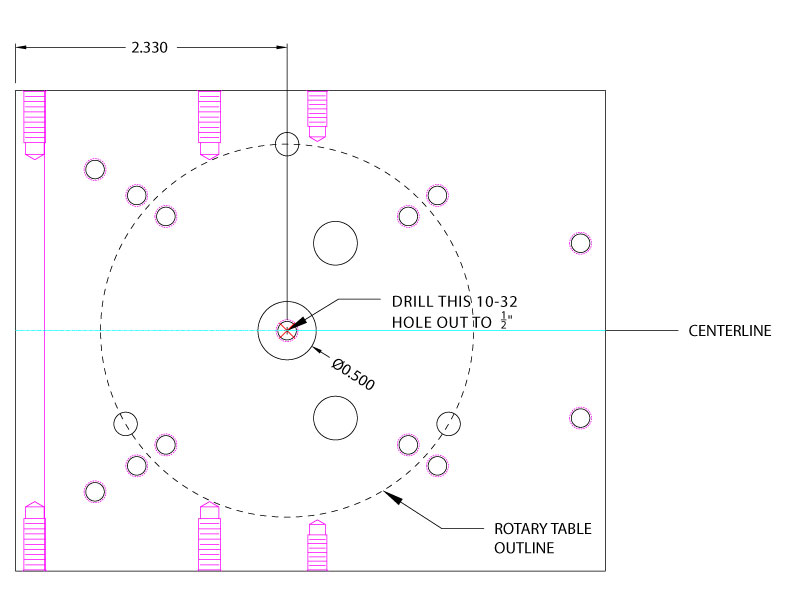

NOTE: In order to use this rotary table with our Tilting Angle Table (P/N 3750) you will need to drill out the 10-32 center hole to 1/2″ diameter. This will allow the maximum diameter of stock to feed through the rotary table (See Figure 2). Back to top |

4" CNC-Ready Rotary Tables

CNC-Ready 4" Rotary Table with Stepper Motor Mount (Click on image for a larger view). |

4" CNC-Ready Rotary TableSherline has taken its P/N 3700 manual 4" rotary table and applied a stepper motor mount with dampened coupling in place of the handwheel. The mount accepts a NEMA #23 frame size stepper motor for CNC control. This allows the table to be used as a 4th axis with CNC systems that have the capability to drive a rotary axis.

NOTE: CNC-ready machines cannot be operated manually until stepper motors are installed. Back to top |

CNC-Ready 4" Reverse Rotary Table with Stepper Motor Mount. The photo on the right shows the P/N 3700-OP (manual) mounted to an optional P/N 3750 Tilting Angle Table (Click on image for a larger view). |

4" CNC-Ready Reverse Rotary TableSherline has taken its P/N 3700-OP manual 4" rotary table and applied a stepper motor mount with dampened coupling in place of the handwheel. The mount accepts a NEMA #23 frame size stepper motor for CNC control. This allows the table to be used as a 4th axis with CNC systems that have the capability to drive a rotary axis. The reverse rotary table is perfect for using on the tilting angle table (P/N 3750). The reverse mount allows access to the handwheel from the front of the machine (see 3700-OP Set photo up).

NOTE: CNC-ready machines cannot be operated manually until stepper motors are installed. Back to top |

The photos on the right are the P/N 3710-CNC Rotary Table with a chuck in place to show the through hole. The chuck is not included. (Click on images for a larger view).

|

4" Nickel-Teflon Coated CNC-Ready Rotary Table w/ 15/32" Through HoleThis is a modification of our P/N 3700-CNC 4" CNC-Ready Rotary Table. This modification came about after requests from our laser engraving customers. They wanted a rotary table that had a larger through hole to which you could mount our chucks.

NOTE: In order to use this rotary table with our Tilting Angle Table (P/N 3750) you will need to drill out the 10-32 center hole to 1/2″ diameter. This will allow the maximum diameter of stock to feed through the rotary table (See Figure 2). Back to top |

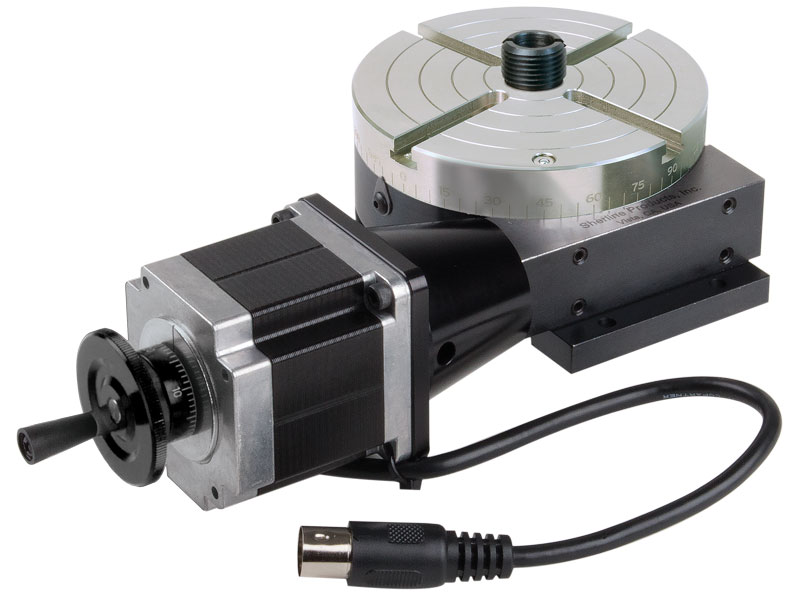

4" CNC Rotary Tables with Stepper Motor

CNC 4" Rotary Table with Stepper Motor (Click on image for a larger view). |

4" CNC Rotary Table with Stepper MotorThis rotary table comes equipped with a 2 amp, NEMA #23 stepper motor. Sherline’s CNC driver box comes equipped with an A-axis output cable ready to drive a 4th rotary axis. The 8730 rotary table is all you need to turn your Sherline CNC mill into a 4-axis machine. Just plug the A-axis cable from the external 8760 driver box or the built-in driver box in your Sherline computer into the matching plug on the stepper motor.

Back to top |

The photo on the left shows the stepper motor in place. The photo on the right is the P/N 3710-CNC Rotary Table with a chuck in place to show the through hole. The CNC-ready version and chuck are shown for reference only; the chuck is not included. (Click on images for a larger view).

|

Nickel-Teflon Coated CNC Rotary Table with 15/32" Through HoleThis is a modification of our P/N 8731 4" CNC Rotary Table with Stepper Motor. This modification came about after requests from our laser engraving customers. They wanted a rotary table that had a larger through hole to which you could mount our chucks. The Nickel-Teflon plating was designed to be used in an every-day production environment. This gives the table a rust resistant surface that is hard and has added lubrication qualities.

NOTE: In order to use this rotary table with our Tilting Angle Table (P/N 3750) you will need to drill out the 10-32 center hole to 1/2″ diameter. This will allow the maximum diameter of stock to feed through the rotary table (See Figure 2). Back to top |

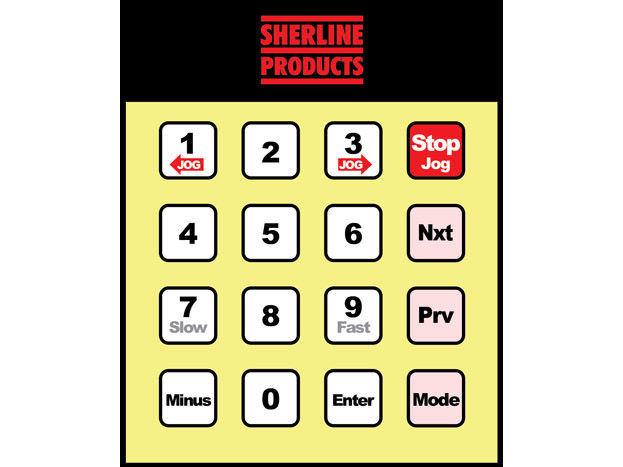

The photo on the left shows the stepper motor and controller in place. The photo on the right shows the controller keypad. All entries are made from this simple keypad. No separate computer is needed. You get everything you need including the 4" Sherline rotary table with installed stepper motor, microprocessor unit with numeric input keypad, 115 VAC power source, and all necessary connecting cables (Click on images for a larger view). |

CNC 4" Rotary Table IndexerSherline has taken their accurate and reliable 4" rotary table into the 21st century with the addition of Computer Numeric Control. Anyone with a need to cut gears or other complicated radially symmetrical patterns will find this accessory takes all the headaches out of repetitive indexing operations. The CNC rotary indexer is a stand-alone unit. You get everything you need to make complex indexing jobs easy. In addition, the unit can be connected to an existing CNC control to act in conjunction with that system. The unit can also be “daisy chained” with other units to trigger sequential actions. As with all Sherline accessories, complete instructions are included.

NOTE: The power supply included with this indexer is intended to operate only on 115/120 VAC, 60 Hz (38 W) current. For countries operating on 100, 220 or 240VAC and/or 50Hz a transformer will be required. As an alternative, this power supply outputs 24VDC, 1 Amp (1000 mA). If you can purchase an appropriate power supply that operates on local current and outputs 24VDC, 1A current, it could be used to power the unit instead of the one supplied. Sherline Products does not provide a 220V power supply or transformer. Back to top |

The photo on the left shows the stepper motor in place. The photo on the right is the P/N 3710-CNC Rotary Table with a chuck in place to show the through hole. The CNC-ready version and chuck are shown for reference only; the chuck is not included. (Click on images for a larger view).

|

Nickel-Teflon Coated CNC Rotary Table IndexerThis is a modification of our P/N 8700 4" CNC Rotary Table with Indexing Controller. This modification came about after requests from our laser engraving customers. They wanted a rotary table that had a larger through hole to which you could mount our chucks. The Nickel-Teflon plating was designed to be used in an every-day production environment. This gives the table a rust resistant surface that is hard and has added lubrication qualities.

NOTE: In order to use this rotary table with our Tilting Angle Table (P/N 3750) you will need to drill out the 10-32 center hole to 1/2" diameter. This will allow the maximum diameter of stock to feed through the rotary table (See Figure 2). Back to top |

Search Our Site